Elmridge iEvac Smoke/Fire Escape Hood

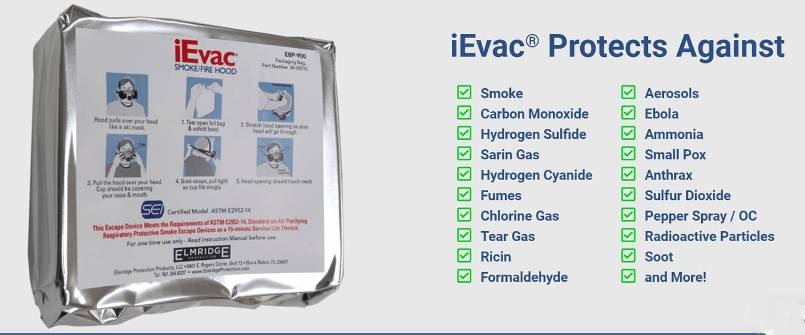

Doubles as a Pandemic and Bioterrorism Evacuation Hood

that protects against Bioterrorism and Pandemic

threats such Anthrax, Smallpox, Viruses, Radioactive particles and more!

The iEvac Hood EBP-900 originally manufactured as an exceptional fire/smoke escape hood can also double as a very effective guard against highly contagious pandemics and terrorists threats.

The iEvac Smoke Mask/Fire Escape Hood is the only smoke/fire

evacuation hood certified to the American Standard ASTM E2952. Years of research

and testing went into creating the iEvac, the most technologically advanced

escape mask on the market today.

It protects against fire-related gases

including carbon monoxide, hydrogen cyanide, smoke, & hydrogen sulfide. The

iEvac contains a HEPA filter that removes more than 99.97% of sub-micron

particles such as ebola, anthrax, smallpox, and radioactive particles.

Providing over 100 times the protection

of an N95 mask, this hood can be used by First Responders, Medical

and specific personnel who would need the additional protection.

One of the key components of the hood is a HEPA P100 filter

which will filter out 99.97% of sub-micron particles,

as compared to the N95 mask which will filter out 95%*. This hood

will also protect against, Anthrax, Smallpox and Radioactive particles!

This hood was originally designed for escape from a fire/hazard situation and is

still being used for this purpose. For a fire situation this is a one-time use

product, however, if used only for the current Covid-19 pandemic situation, the

Pleated HEPA filter with proper sanitizing, will last

for weeks if not months!

* In

addition, with a hood you are also protecting the person’s eyes and ears. The

silicone neck dam provides an excellent seal, preventing any agent from leaking

into the hood.

Designated as a Qualified *Anti-Terrorism Technology by the US Dept. of Homeland Security, office of the Safety Act

* Niosh approved for protection against Chemical, Biological, Radiological and Nuclear Attacks.

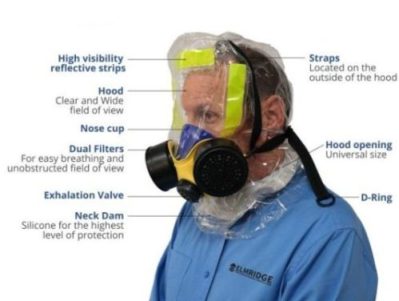

One universal size can be put on in under 30 seconds. The hood features easy-to-breathe dual filters and is compact, lightweight, and vacuum sealed in a foil bag for a long shelf life. Its unobstructed field of view can be used with eyeglasses, beards, and long hair.

This pandemic should be a wakeup call for everyone - Be prepared, not only for this pandemic, but for any future catastrophes that could possibly occur!

Shelf Life: 5 1/2 years

Features:

- Maintenance-free

- Twin cartridges for easier breathing

- Improved field of view than with single cartridge in front

- Hood is a clear material resulting in an unobstructed field of view

- High visibility reflective strips for easy recognition

- For easy access – head harness adjusts outside the hood

- Protects lungs, head, eyes, and face

- One universal size

- Quick and easy donning 30 seconds

- Can be used with eyeglasses, beards, and long hair

- Packaged in puncture- and- water-proof laminate barrier

- Latex-free

● US Dept. of Homeland Security

![]()

$199.99

Additional Information:

What independent tests have been performed on the iEvac®?

Certification

The iEvac® is certified as an

Air-Purifying Respiratory Protective Smoke Escape Device. This certification

is issued by the Safety Equipment Institute (SEI) and certifies that iEvac®

is in complete conformance with the American National Standard for

Air-Purifying Respiratory Protective Smoke Escape Devices. This

certification is earned after extensive independent testing to prove

compliance with every requirement in the Standard. This testing was

performed by Intertek and Assay Technology

Total Performance

The iEvac® Smoke/Fire Hood has a

recorded protection factor greater than 90,000. iEvac® is a smoke escape

hood, an air purifying respiratory device for evacuation in case of an

emergency. Its overall effectiveness depends on the filters, the nose cup

and the neck dam. Each of these three integrated elements must play a part

in order for the entire hood to be protective. The overall effectiveness is

determined by a Fit Test, and is measured by checking the performance during

a series of standardized exercises. The Fit Test result is expressed as the

protection factor of the iEvac®. For reference, OSHA has assigned a

protection factor of 10 for N95 masks and 50 for rubberized full face masks.

Another benchmark is the NIOSH test requirement for CBRN APER masks

(respirators for escape from toxic and dangerous atmospheres containing

chemical, biological, radiological and nuclear hazards). NIOSH requires a

protection factor of 2,000 for these masks. The U.S. Army Research,

Development and Engineering Command - Edgewood Chemical Biological Center in

Aberdeen, Maryland conducted tests of the iEvac® using the NIOSH methods and

procedures. Under these rigorous protocols, they measured the fit test

protection factor for the iEvac® as being greater than 90,000.

ANSI 110 Total Performance Requirements

The total performance of a respirator may be

determined by calculating its total inward leakage. This is determined by

measuring the concentration of a challenge substance outside of the

respirator, the concentration within the breathing zone and comparing the

two results. Clearly, the best respirators are those with a very low Total

Inward Leakage.

The iEvac® Smoke/Fire Hood has a recorded Total Inward Leakage measured inside the nose cup of less than 0.01%. This characteristic was measured by the U.S. Army Research, Development and Engineering Command - Edgewood Chemical Biological Center in Aberdeen, Maryland. For reference, the requirement for certification to the ANSI 110 standard is that the Total Inward Leakage inside the nose cup shall not exceed 2%.

It is also important to consider the possibility of leakage through the neck seal into the hood. If this were to happen, the wearer’s eyes could be affected and vision obscured by smoke. This characteristic is different from the Total Inward Leakage which is measured inside the nose cup. This measurement taken within the hood but outside the nose cup is known as the ocular leakage. The U.S. Army Research, Development and Engineering Command - Edgewood Chemical Biological Center in Aberdeen, Maryland measured and recorded the ocular leakage of the iEvac® Smoke/Fire Hood as less than 0.1%. For reference, the requirement for certification to the ANSI 110 standard is that the ocular leakage shall not exceed 20%.

Gases

The iEvac® filters are a proprietary blend of

materials specifically formulated to be effective against a wide range of

gases and particulates. (Tests against particulates are described below.)

Probably the two most dangerous gases encountered during an emergency escape

from a fire are carbon monoxide and hydrogen cyanide. These special filters

will provide protection against both these gases. They are designed to

provide protection against these life-threatening products of combustion and

also against other toxic industrial gases and terrorist gases.

iEvac® filters have been independently tested against gases.

Among the tests are the following:

- carbon monoxide – a very toxic

by-product of combustion

tested at 3,000 ppm,5,000 ppm, and 10,000 ppm

- hydrogen cyanide – a very toxic

by-product of combustion

tested at 400 ppm - sulfur dioxide – a benchmark acid

gas

tested at 100 ppm - acrolein – a benchmark organic

vapor

tested at 100 ppm - cyclohexane – a benchmark

hydrocarbon gas

tested at 500 ppm - hydrogen chloride – a benchmark

acid gas

tested at 1,000 ppm - ammonia – benchmark toxic

industrial gas

tested at 1,250 ppm - chlorine – benchmark toxic

industrial gas

tested at 200 ppm - phosgene – benchmark toxic

industrial gas

tested at 125 ppm - formaldehyde – a benchmark toxic

industrial gas

tested at 250 ppm - phosphine – a benchmark toxic

industrial gas

tested at 150 ppm - DMMP – a simulant for Sarin nerve

gas

tested at 1,000 ppm - hydrogen sulfide – a benchmark

toxic industrial gas

tested at 1,000 ppm and 5,000 ppm - tear Gas (CN) – an irritant toxic

chemical

tested at 16 ppm - tear Gas (CS) – an irritant toxic

chemical

tested at 3 ppm - carbon dioxide – a special

consideration is build-up of carbon dioxide inside the hood. We exhale

carbon dioxide naturally, and it is important to make sure that this gas

does not build up inside the hood. iEvac® is tested to make sure that

the levels inside the hood are safe for the duration of an escape.

Particles

The iEvac® filters are a proprietary blend

of materials specifically formulated to be effective against a wide range of

particulates and gases. (Tests against gases are described above.) In

keeping with its design excellence, the iEvac® filters contain the best

possible particle filter, a high efficiency particulate air HEPA filter.

This is the same material used in military gas masks to provide protection

against biohazards. The HEPA filter will remove 99.996% of particles that

are 0.2 microns in size. It is this ability of the filters to remove

sub-micron particulates that keeps out the small particles that may be

present in smoke. Also, the filters will remove very heavy particles such as

soot. During this test, the filters must remove the soot from the air and

still not clog the filters so that it is too difficult to breathe.

Breathing Resistance

The iEvac® filters are very

protective and also designed for easy breathing. This is important in all

applications but is particularly necessary in emergency situations when the

wearer may be inclined to panic. The iEvac® is tested for both inhalation

and exhalation resistance.

Physical Hazards

Many physical hazards may be

encountered when escaping from a fire. There will be flames, heat, hot

material dripping, and other hazards. Vision will be very important, as will

the need for the packaging to stand up to vibration and puncture threats

from sharp objects.

Inhalation Temperature

It is important to establish

that the air that comes through the filters does not become overheated by

the filtration process. This is established by passing 5000 ppm carbon

monoxide at a temperature of 77°F (25°C) and checking for an increase in air

temperature.

Flammability

Tests for heat and flame resistance.

During theses tests components will not have an afterflame longer than 5

seconds. No component will drip, melt or develop a visible hole or be

damaged so that eyes or lungs are exposed to smoke. These tests involve a

temperature of 1475°F (800°).

Molten drip

In this test, a flaming drip from an

ignited polypropylene rod is allowed to drop onto the hood. No after flame

lasts longer than 5 seconds.

Radiant heat

The hood is exposed to a radiant heat

panel comprising two quartz lamps with a surface temperature between 980°F

(527°C) and 1700°F (927°C) determined from a spectral emittance curve. The

hood is located 9.5 inches away from the radiant heat panel and exposed for

15 seconds. The requirement is that the hood is not damaged in a way that

exposes eyes or lungs to gas or smoke and that the temperature at the top of

the head and inside the eyepiece shall not exceed 158°F (70°C). The hood

passed.

Putting the hood on very quickly

The hood can be

unpackaged and put on in less than 30 seconds

Optical properties

Light transmission, haze and field

of vision are all tested to make sure that the viewing area is big enough

and durable enough.

Fogging

A test is conducted to ensure that a person

can clearly read a standard eye chart while wearing the hood.

Corrosion

The hood is exposed to a corrosive salt

spray, and tested afterwards

Vibration

This test involves vibrating the packaging

for 10,000 cycles.

Puncture and tear

The package is raked by a sharp

pointed heavy striker. The packaging does not puncture, rip or tear

Operational Package Leakage

The package is immersed

in water heated to a temperature of 160°F (70°C) to a depth of 24 inches

(600 mm) and must not leak.

Temperature exposure

The packaged hood is exposed to

a temperature of 32°F (0°C) for 24 hours then exposed to 180°F (70°C) for 24

hours. Then the hood is unpacked and tested for performance.

Pressure conditioning

The packaged hood is exposed to

100 cycles of differential pressure. Each cycle is 60 seconds at ambient, 20

seconds going from ambient to 300 mbar below, 60 seconds at 300 mbar below

and 20 seconds back to ambient. Then the hood is unpacked and tested for

performance.

More Test Data

We are continuing to develop more test

data for the iEvac® Smoke/Fire Hood and we will add these to our web site as

they become available.

Precautions

Of course, no filter and no hood can

provide 100% protection, so be sure to follow the instructions in the User

Manual.